#Successstory - How Ensinger-Sintimid GmbH helps Deep Space Exploration

Maybe it has happened to you when cooking or baking: You have just been inattentive for a moment and put the mixing bowl on the wrong place. It is distorted, it stinks like hell in the kitchen and the hot plate is full of plastic. Closer to the Sun it is a lot hotter. Ikarus, the son of the Greek inventor Daedalus experienced this when he approached the Sun to close. His attempt to fly ended in disaster and he dropped into the sea. Ikarus had chosen the wrong material. Space parts also need to be heat-resistant and light.

Protection against Temperature Fluctuation

How can orbiters and their technical equipment be protected against high temperatures? Are plastics an appropriate material to use for this purpose? The solution for this problem comes from Upper Austria and is called TECASINT. This is the registered trade name comprising a group of non- melting high-temperature Polyimides. This material is produced by Ensinger-Sintimid GmbH in Seewalchen am Attersee (Upper Austria), a subsidiary enterprise of Ensinger GmbH in Nufringen, Germany. It was founded in 1966 near Stuttgart and now has over 33 locations around the world.

TECASINT on the Way to Mercury

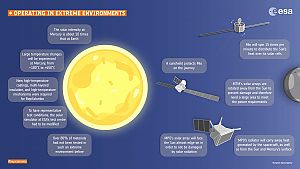

In order to gain more information about the smallest Telluric planet in our solar system, Mercury, two planetary orbiters were sent there on a joint mission by ESA and the Japanese Space Agency, JAXA. The mission launched on 20 October 2018 from Guiana Space Centre Kourou. Both spacecraft, the Mercury Planetary Orbiter and the Mercury Magnetospheric Orbiter, are expected to arrive at Mercury in 2024. As Mercury is the nearest planet to the sun in our solar system the orbiter will have to endure temperatures up to 350 degrees Celsius. The orbiters will collect data for at least one year.

The mission will only be successful if the Thermal Control System (TCS) of the orbiters works correctly. The TCS ensures that the components within the orbiters, e. g. optical sensors or atomic clocks can operate at the correct temperatures as they are very susceptible to thermal fluctuations above and below optimum working temperature. It is also possible that the solar panels do not extend accurately if they get too hot. However, temperatures vary massively on this mission, dependent on whether the orbiters are passing through deep space or approaching other planets whilst constantly being subjected to the effects of Solar Flux.

A Stable Heat-Shield

One of the components in the TCS is the thermal spacer, which is a washer that functions as a barrier to high temperatures and current. The plate is made from TECASINT. This thermal spacer has to withstand high loads and it must not creep at high temperatures, it must not deform in any way. Moreover it is important that components are wear resistant. Functionality of these parts is guaranteed for a period of six or seven years.

TECASINT 1011 was chosen for the thermal spacer as the material is non-melting and does not soften, even at temperatures approaching 350°C. The material demonstrates very low creep tendency under load, which is important for this application, as it is intended to hold a high screw force for several years.

Properties of TECASINT

What makes TECASINT so special? In order to meet ESA's requirements and standards the plastic has to exhibit low outgassing properties. "In deep space there are vacuum conditions, any outgassing or emissions could impair crucial applications, that means sensitive optical components like e. g. lenses and objectives could steam up just like a camera lens and therefore would not perform efficiently", says Axel Reinheimer, Technical Support and Sales Manager at Ensinger.

The material has to be solid and elastic at the same time. TECASINT is a moderately elastic plastic material, which it is, compared to metals. Furthermore, TECASINT exhibits good electrical insulation performance preventing severe damage to electronic devices. And least but not least the material is characterized by a high thermal insulation.

New high performance Polyimides

"Brimatech as the ESA Technology Broker for Austria supports Austrian organisations to take part in future missions. The development of high performing Polyimides has not come to an end since the mission to Mercury has taken off" says Susanne Katzler-Fuchs, Brimatech CEO.

The new materials, like for instance TECASINT 4111, have even lower outgassing properties, which are more suited to vacuum and cryogenic applications and operate at even higher temperatures – that is to say: up to 470 degrees Celsius. Why these new sorts of materials were not specified for the mission to Mercury? "At the beginning of the development for the Bepi Colombo mission in 2009/2010 these materials were not available commercially. During the testing phase of a satellite mission, materials that were recommended and chosen at the beginning were not changed as long as they perform appropriately", Reinheimer explains. These new kinds of materials shall now provide for other missions in space so that an old human dream comes true: to fly to the Sun without crashing.

For more information about ESA Space Solutions and related Business Applications, Business Incubation and Technology Transfer please visit ESA Space Solutions.

The European Space Agency (ESA) Technology Broker for Austria, is delivered by Brimatech and is part of ESA Space Solutions Centre Austria, managed and funded in collaboration with: